Hosokawa Micron Pre-Breakers are size reduction units designed for light to heavy duty requirements.

The Pre-Breaker from Hosokawa Micron is just one of the products in our portfolio of horizontal shaft crushers that is tailored for coarse size reduction. The reliable Pre-Breaker performs a similar cutting and shearing operation to both the Hosokawa Micron Rubber Chopper and Hosokawa Micron Extructor, but what sets the Pre-Breaker apart is the broad range of light to heavy duty materials it can process – everything from fruits and vegetables, seaweed, opium, bones and plastics, to wood, insulation boards and press cakes. The PB24 Pre-Breaker model, in particular, is extremely popular with customers across the world for bovine and porcine by-product processing as a means to process skins and hides for the manufacture of gelatine powder, used as an ingredient of some pharmaceuticals and food products. Available in a number of sizes, motor and speed ranges – including a bottom discharge design for high capacities – the Pre-Breaker is robust enough to withstand shock loads and has the capability to generate enough torque at low speed to process even very tough materials. The equipment’s components are extremely hardwearing, low maintenance and energy-efficient, too, providing many years of high-performance and economical service.

For the crushing of materials such as bales of rubber, we recommend our specialised Rubber Chopper, while for materials that require more careful handling during processing – such as frozen fruit, meat and blood plasma – our Extructor would be the best option.

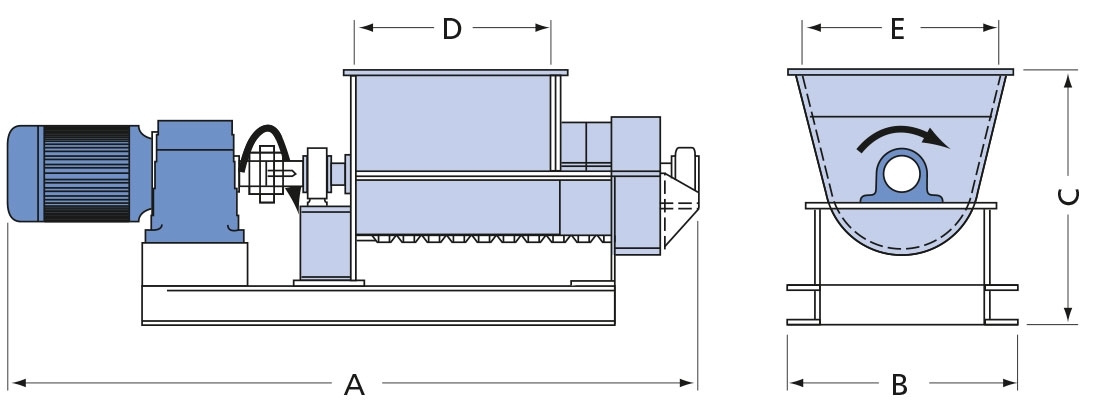

Prebreaker Specifications

The Pre-Breaker is currently available in five models – PB10, PB12, PB15, PB18 and PB24 – which encompass five sizes. The smallest model (PB10) can be supplied with a motor of between 7.5kW and 15kW (40 to 80 rpm), while the largest and most powerful model, the PB24, offers a motor range of 90kW to 150kW (120 to 230 rpm).

Optional Features

Chemical and hygienic designs are available. Please ask the Hosokawa Micron sales team for advice and further details.

The Hosokawa Micron Pre-Breaker is perfect for light to heavy-duty crushing and pre-crushing duties (prior to fine micronising, for example) and is capable of cutting and shearing all manner of raw materials that require size reduction, including difficult-to-process materials such as seaweed and wood, as well as material prone to crumbling. (it is not suitable for processing metals or fibrous materials such as rope). The Pre-Breaker is used by a number of manufacturing industries, who use it during the manufacture of end products including medicine, animal feed and cosmetics, as well as for recycling wallpapers, rejects and insulation boards.

Key Features

Hosokawa Micron Pre-Breakers are used to process waste cabbages for use as supplementary feed for cows. Cabbages are a highly nutritious, digestible and readily available addition to the grass-based diet of cows, which tolerate the vegetable extremely well, given in the correct proportions. The brassica is an increasingly popular crop for livestock farmers around the world, especially during dry weather conditions when there is often not enough grass for feed.

The Pre-Breaker is a versatile, resilient piece of equipment built from carbon or stainless steel. This exceptionally reliable workhorse will provide many years of service and is suitable for the coarse reduction of diverse materials, from soft and friable to hard, tough and difficult-to-process.

Similar to its coarse processing sister products, the Rubber Chopper and Extructor – which are specialised to meet the needs of particular raw materials – the Pre-Breaker has design characteristics that enable it to process and pre-process a more general, wider range of raw materials, when considerations such as product damage or bruising are less of an issue.

The Pre-Breaker incorporates an inlet hopper, into which the feed material is introduced. The material transits through into the body of the processing chamber, where it comes into contact with a series of hard-faced, hooked hammers and fixed, hard-faced anvils, which are integrated into the rotating horizontal shaft and systematically crush, shear and cut the processing material as the rotor transports material through the chamber to the discharge.

Torque is dependent on the particular model configuration chosen and the material being processed – a low rotational speed gives a high torque output, allowing for an efficient operation with minimal wear to the components. Currently, the Pre-Breaker is available at a maximum power of 150kWs, making it suitable for more demanding materials.

Once the processing material is conveyed along the horizontal shaft, it arrives at the discharging outlet where the particle size of the exiting processed material is controlled by the orifice plate.

Thereafter, the material can continue on its processing journey, which may include milling, for example.

Hosokawa Micron’s Pre-Breaker is most often used as a standalone piece of equipment, but we do have the expertise, capability and product ranges to integrate the equipment into a process system, if required.

We are a processing and containment equipment specialist for powders and particles, with broad-based, in-depth industry knowledge and a comprehensive portfolio of equipment specifically for a multitude of processing sectors and applications.

The Pre-Breaker, for example, offers a highly efficient way to break down cocoa press cake, prior to the reduced material being finely milled into cocoa powder for the confectionery sector. A specialist micronising mill, such as a Hosokawa Alpine ACM Air Classifier Mill, is required for the fine milling of the material into ultra-fine powder. This ensures an end product (such as a chocolate bar) has the all-important optimal ‘mouth feel’.

Our highly experienced equipment specialists would be pleased to design a bespoke process system for your unique application requirements.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on