The Nobilta™ is a multi-functional processing unit for high speed, precision, powder mixing, particle surface modification and shape enhancement. Particles are combined into composite materials in a dry process without the use of a binder by applying mechanical force.

Nobilta™

Composing

Nano-scaled particles are permanently fused onto the surface of micron-scaled particles without binders, combining material properties of different particles into one particle to enhance chemical reaction, flowability, heat resistance, electric performance and solubility.

Precision Mix (Dispersion)

Enabling distributive and dispersive mixing in one apparatus to improve colour, tone, reactivity, calcinations ability and mechanical intensity.

Shape enhancement (Sphericalization)

Improving round shape and reducing BET surface area for enhanced flowability and packing density.

Typically used for high value materials and products such as toner, pharmaceuticals and fine ceramics the Nobilta™ has become established as a recognised route for applications across a range of industries.

Nobilta™ Typical Applications:

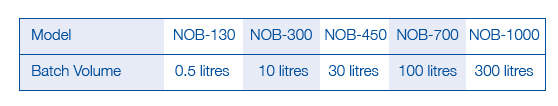

Nobilta™ Specifications

Options:

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on

Complete a short survey about our website?

We are constantly looking to improve your experience with Hosokawa Micron and would appreciate 3 minutes of your time to complete this anonymous survey. Thank you, Hosokawa Micron Ltd

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |